What is Serialized Manufacturing in the Supply Chain?

The manufacturing industry has millions of moving parts. From minuscule nuts and bolts to giant finished products, manufacturers must define a meticulous system to track their inventory of individual components. Serialized Manufacturing is a way to trace the end-to-end product and its components during the product’s complete life cycle regardless of if the product is within the plant or with the customer.

The system keeps a record of the whereabouts of units. This has become the baseline for the capital goods industries that would like to trace the product along with its components throughout the product’s lifecycle.

Key Components of Serialization

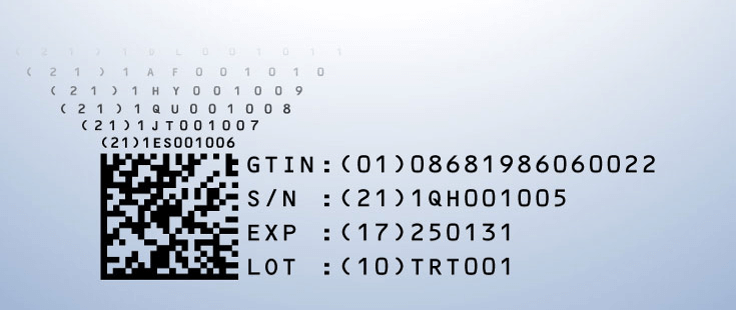

Individual components are assigned a series of unique identifiers during the lifecycle. These unique identifiers are critical in tracking the product throughout its journey from production to customer.

You’re likely familiar with these identifiers already, even if you hadn’t noticed them before:

- Global Location Number (GLN)

- Global Trade Item Numbers (GTIN)

- Serial Number

- Lot/Expiry

Benefits of Serialization

Serializing the individual components at this level offers several benefits to manufacturing companies. When implemented effectively, serialization can see the following benefits:

Product life cycle tracking

Serialization allows manufacturers to see their product or product components from creation to end user. They can track the product’s movement through the supply chain, know when it reaches the customer, and even when that product is returned or retired.

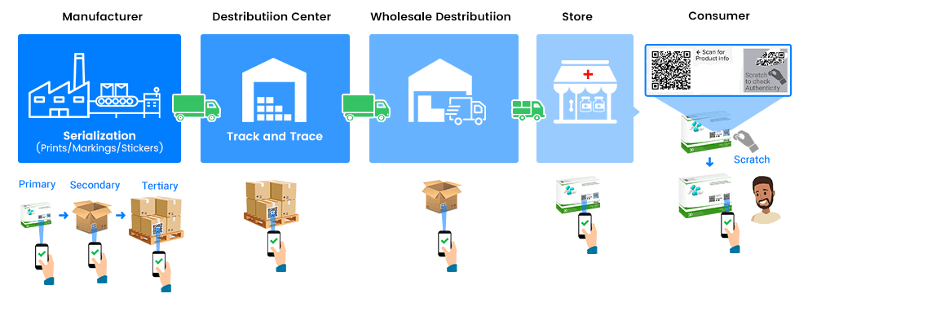

Enhanced tracking through the Supply Chain

This method allows products to have a digital footprint – manufacturers can see the product or component from the time it leaves their facility to the time it reaches their customers and see every stop along the way. They’ll be instantly notified of delays or changes, and can proactively communicate with their customer.

Product maintenance

Over time, machinery products need to be serviced. With component and product serialization, manufacturers know where their products are and when they arrive, thus allowing them to offer a proactive maintenance schedule to their customers. Companies can even manage their warranty and service agreements via these unique identifiers, tracked in their management systems.

Additional benefits of serialization include:

- Improve product safety, quality, and authenticity

- Improves Product Recall Management

- Ensure compliance with government and Industry regulations

Industries Benefiting from Serialized Manufacturing

Many diverse manufacturing businesses have adopted this management practice. We’re seeing a rise in these specific industries:

- Pharmaceuticals/Medical Industry

- Capital goods in semiconductor/Automobile product

- Oil & Gas Machineries

- Aerospace Equipment

- Consumer Goods Manufacturing

- Infrastructure Equipment

Managing Serialized Manufacturing with Oracle:

Oracle is a leading enterprise management technology platform that offers a comprehensive and fully integrated stack of cloud applications and cloud platform services. Within their Supply Chain Management or Manufacturing Cloud products, there are several components that can help manufacturers address serialization:

- Serialized Items: Products or components are assigned unique identification codes (serial numbers or lot numbers) for individual tracking.

- Predefined Serial Number Generation: Automatic predefined generation based on your configuration (integration with external devices is also possible).

- Inventory Transactions: Track movement and status changes (e.g., shipped, received) of serialized items throughout the supply chain.

- Traceability: The entire lifecycle of a serialized item can be traced, providing valuable data for warranty management and regulatory compliance.

- Real-time Visibility: Gain insights into serialized inventory levels throughout the manufacturing process and beyond (warehouses, production lines). Track the location (e.g., warehouse bin) and status (available, allocated) of each serialized item.

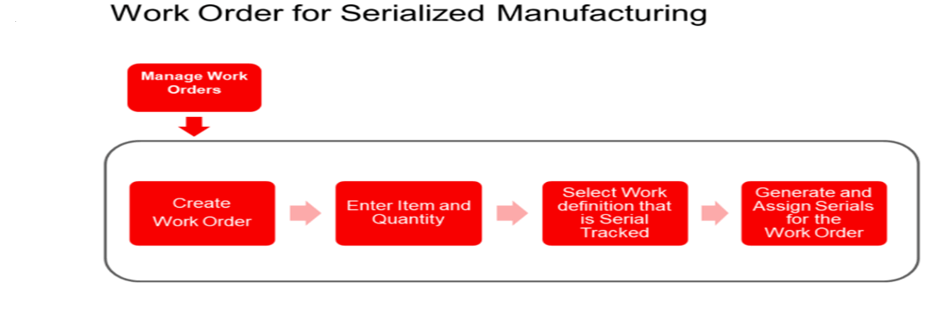

Conceptual Flow of Serialized Manufacturing

What might serialized manufacturing look like in practice? Here’s a flow diagram illustrating the typical process within Oracle Fusion Cloud SCM:

How to Enable Serialization in Oracle Manufacturing Cloud

If you are looking to implement these practices in your organization with Manufacturing Cloud, we’ve identified some key tasks for you to get started with this process.

- Configure Item Attributes. Define the item as “serialized” in the system.

• Choose the Predefined serial number generation method (automatic)

• Enable product Life cycle tracking and Asset Management and traceability - Work Definition

• Enable Serialized Work definition and serialized operation

• Once the item is enabled for serialization below transactions capture serialization information. - Production Process

• Track the movement of serialized components through each production stage.

• Capture any additional data associated with the serialized items (e.g., inspection results) - Inventory Management

• Track and manage the inventory levels of serialized items throughout the supply chain (warehouses, production lines)

• Update inventory records for movements (e.g., shipments, receipts)

Reporting and Analytics

Oracle provides the capabilities to generate reports on serialized inventory details and analyze data to identify trends, optimize inventory management, and ensure compliance.

By following these steps, you can enable and configure serialization in Oracle Manufacturing Cloud, allowing you to track and manage serialized inventory items effectively.

In today’s competitive landscape, serialized manufacturing offers a valuable tool for businesses across various sectors. By implementing this technology, organizations can gain a significant edge through improved traceability, efficient operations, and robust compliance practices. This ultimately leads to better customer satisfaction, brand protection, and a more sustainable supply chain.